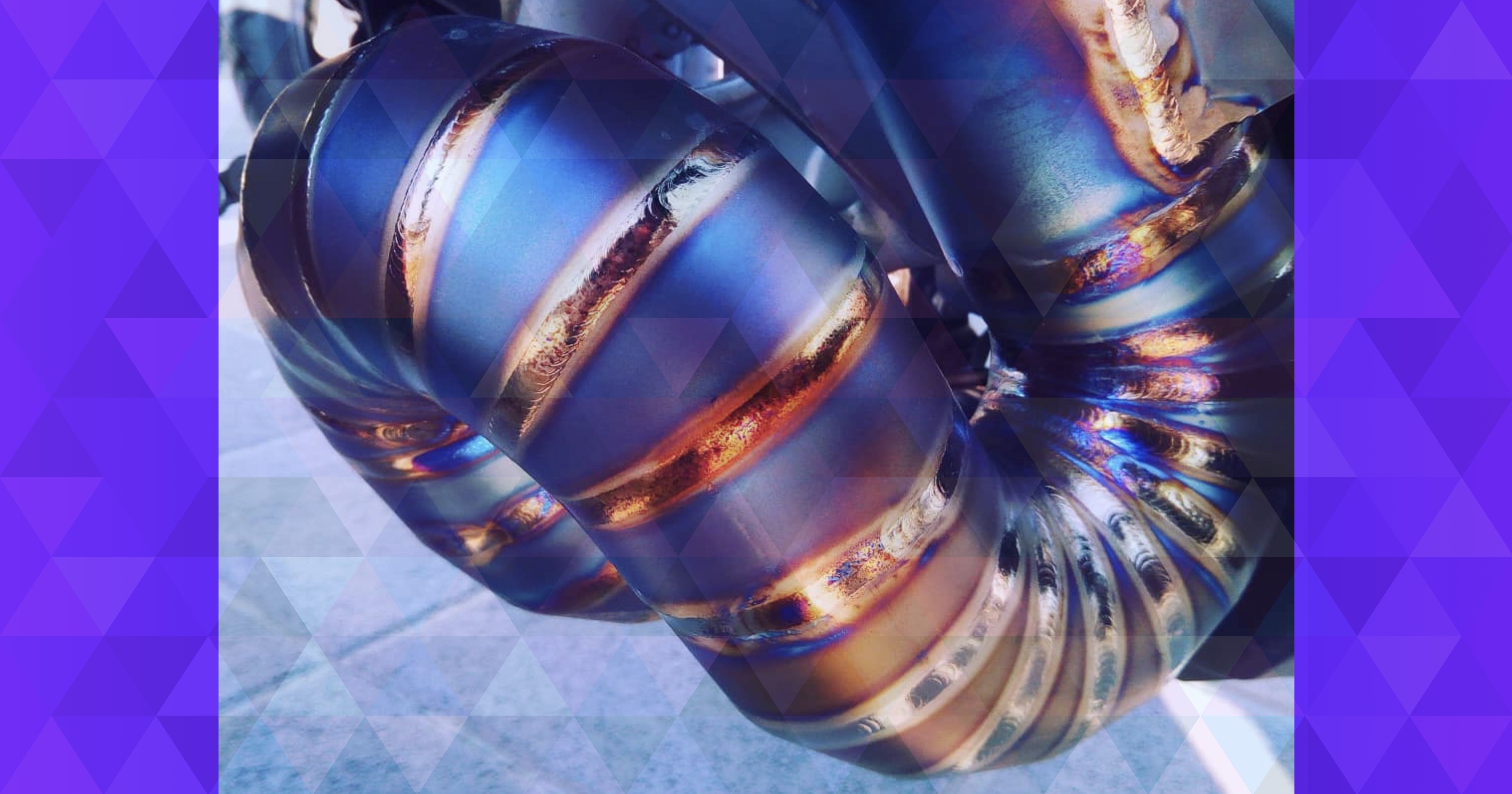

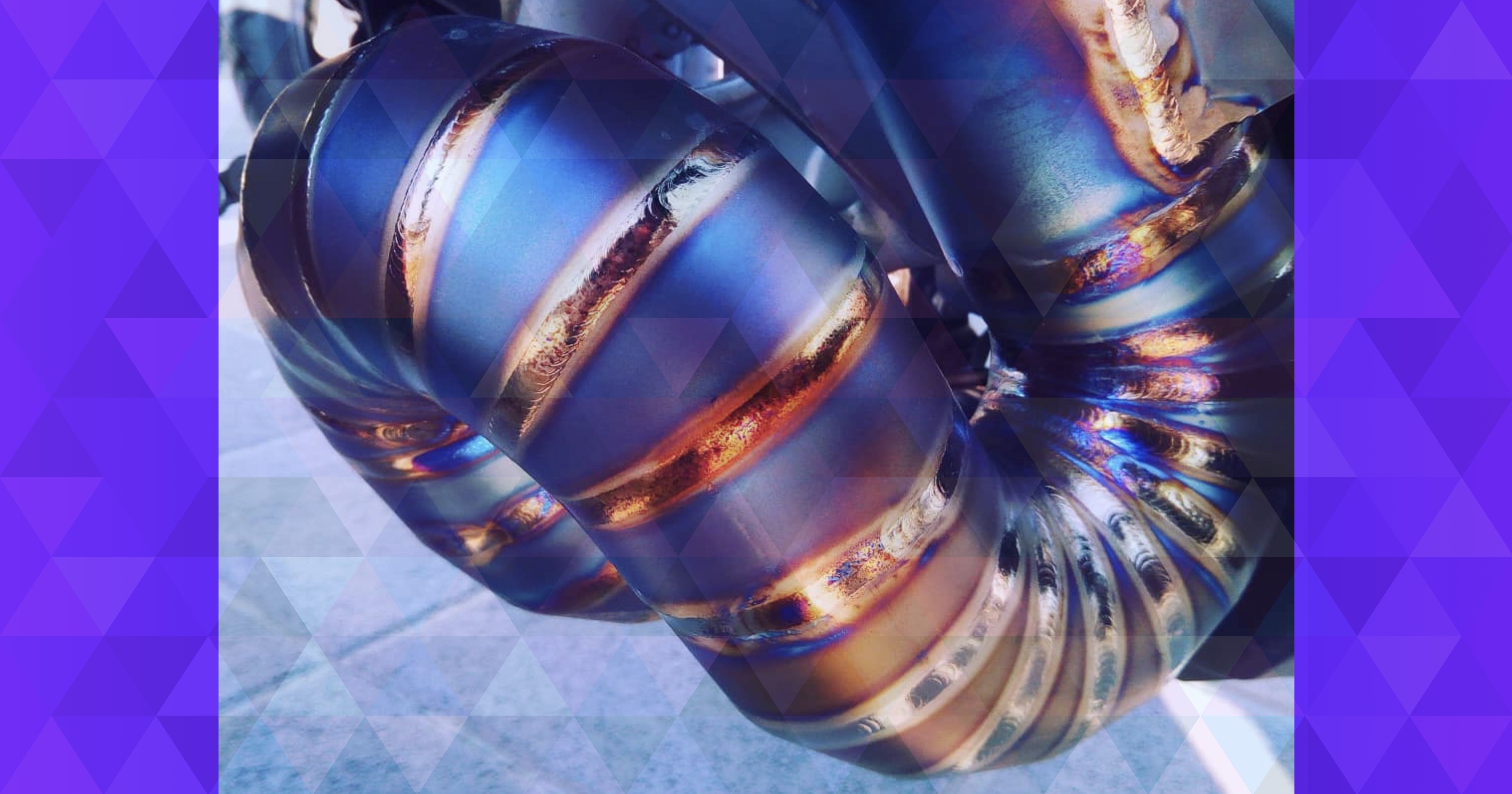

We are a company specialising in tig welded copper boilers, using our unique welding process. These are used primarily in large working models, stationary steam plant, ships, traction engines, steam launches and live steam locomotives.

We can supply boilers to any of the standard model engineering designs, copy old boilers from the original or build to drawings for new designs.

- All boilers are fully tested and certified.

- All boilers are built to CE standard, as required (over two litres capacity).

- With all component parts of the boiler made in copper and fully welded these boilers offer an extended life far superior to other boiler construction methods.

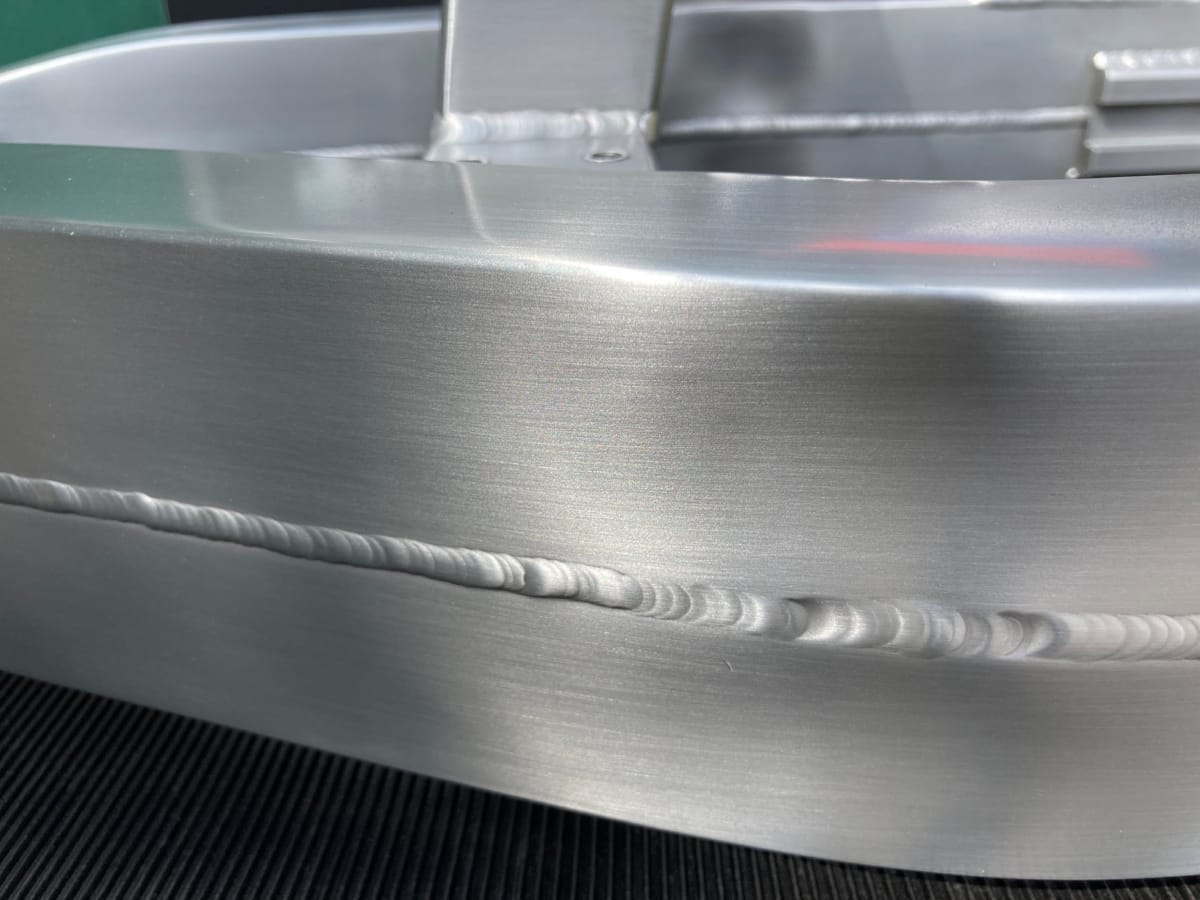

We have many years of experience of building this type of boiler and can claim to produce a boiler second to none in strength and reliability. We are also able to produce fuel and water tanks, and other items in stainless and aluminium as well as copper.